Visit of Mona Neubaur

Today's exchange between the NRW Minister for Economic Affairs, Industry, Climate Protection and Energy and colleagues from our company focused on the topic of attracting and securing skilled workers. As part of her summer tour, Mona Neubaur asked about hurdles and creative ideas for attracting the best minds.

Trainees Paul-Eric Meyn and Tabea Bogers explained what a day of training is filled with and why they chose their professions.

To further emphasize the value of training, there will be a dedicated training workshop at Wystrach as part of the new building, as Managing Directors Wolfgang Wolter and Matthias Kötter told us.

At the same time, we were able to welcome around 20 new colleagues today - we wish them all a good start!

Millions invested in the energy transition

Weeze, Germany. Investing in the location: Hexagon Purus is building a new production hall at its site in Weeze for around EUR 12.5 million. With it, the hydrogen systems specialist intends to significantly expand its production capacity. It will also increase the number of employees from 240 to 350. Further investments in office and training facilities, a parking garage, and a hydrogen refueling station are planned as well. “This construction project shows that we want to grow in the region, offer future-proof jobs, and drive the energy transition,” emphasized Michael Kleschinski, Executive Vice President of Hexagon Purus, at the symbolic groundbreaking ceremony.

The start of a multimillion-euro investment is reason enough to take a moment and celebrate with employees, neighbors, and other guests. To mark this special occasion, Member of the German Bundestag Stefan Rouenhoff, District Head Administrator Christoph Gerwers, and Mayor Georg Koenen visited the hydrogen and high-pressure specialist company, which was founded in 1988 as Wystrach and has been part of Hexagon Purus for the past year and a half. Representing Hexagon Purus at the event was Executive Vice President Michael Kleschinski. All four guests of honor highlighted the importance of the investment for the region and the crucial role green hydrogen plays in the energy transition and climate protection.

Hydrogen plays a key role as an energy source

Bundestag Member Rouenhoff said: “The Bundestag’s Committee on Economic Affairs is deep in discussions regarding how to successfully overcome the enormous challenge of decarbonizing the German economy, especially industry. Hydrogen plays a key role in these efforts as an energy source. Hexagon Purus is a highly innovative player in the hydrogen industry and is now taking the next big step in Weeze by expanding its production of hydrogen systems. This is a good day for the Kleve district. The company is a driving force in the industry that can help make the Lower Rhine region a hydrogen region.”

In his remarks, District Head Administrator Gerwers pointed out that “for years now, the company’s modern buildings have been catching the eye of people driving past. I’m delighted to see innovative companies like Hexagon Purus starting up and growing here in Kleve. After all, it’s pioneers like these that tackle the issues shaping the future with impressive innovative strength and thus create and secure jobs.”

Three construction phases

The expansion of the company site in Weeze will be completed in three stages. The first concerns a 5,000 m2 production hall, scheduled to be completed in October of this year. Beyond that, the company will be building social spaces and bathrooms for around 120 employees, as well as 30 office workstations, training and meeting rooms, and a storage area.

Work on specific plans for the second construction stage will start this summer. That will include an office and training center with 80 office workstations and a parking garage with 160 parking spaces. In the third stage, there are plans to construct a public hydrogen refueling station. Overseeing the construction project is the architectural office Hanßen based in nearby Geldern.

Investment for the first construction stage runs to approximately EUR 12.5 million. The expansion will grow the current production area from 11,000 to 16,000 m2, but the resultant production capacity is disproportionately greater. “We’re responding to the rise in market demand,” explains Wystrach CEO Wolfgang Wolter. Especially in energy-intensive sectors such as steel production or the chemical industry, green hydrogen is rapidly gaining in importance. Weeze’s mayor, Georg Koenen, looks upon the development of the company with pride: “The substantial investment in the expansion of the site in Weeze, amounting to some EUR 12.5 million, underlines the attachment of Wystrach to its hometown even after the merger with Hexagon Purus. The company is a gamechanger in the energy transition and a drawing card for Weeze and the entire Lower Rhine region.”

Mitigating climate change

Numerous climate-conscious measures are being implemented in the new construction. A photovoltaic system will feed an air-to-air heat pump and the air-conditioning units for the office wing and the social spaces. In the production hall, the concrete ceilings and walls are to be used as energy storage by means of concrete core activation. Heat recovery from the heating infrastructure is another pillar of the concept for the production hall. “We’re also in the initial phases of drawing up a larger photovoltaic concept,” Wolter said.

Creating jobs

The investments will significantly boost the number of employees at Hexagon Purus in Weeze. At the end of 2022, the company recorded a headcount of 243. By the end of this year, that number is expected to hit 350. “In this way, we’re making it clear that we remain loyal to our home location and are offering future-proof jobs in an exciting industry,” Wystrach CEO Jochen Wystrach says. The company is looking for people in areas ranging from production to administration: mechanical and mechatronics engineers, MAG welders, PLC programmers, IT specialists, designers, business experts, planners, and team leaders. “We welcome all applications,” he says, “whether for a skilled position or one of our apprenticeships.” With this expanded workforce, Hexagon Purus can continue to drive the energy transition from Weeze.

Applicant Day

Hexagon Purus is holding its next Applicant Day in Weeze on May 6. Starting at 10 a.m., interested parties can take a look around the company premises and its production facilities and talk to employees from various departments. Please register in advance at www.wystrach.gmbh.

Matthias Kötter named new Managing Director

Weeze/Oslo

Hexagon Purus is pleased to announce the appointment of Matthias Kötter to the position of Managing Director at Hexagon Purus in Weeze. This appointment sets the stage for founders, Wolfgang Wolter and Jochen Wystrach to transition their responsibilities to the new leadership.

"We are pleased to have found such a competent leader as Matthias Kötter within our organization to fill this role”, said Michael Kleschinski, Executive Vice President Light Duty, Distribution & Cylinders of Hexagon Purus. "Our business in Weeze is central to our aspirations for our hydrogen systems business in Europe and with Matthias at the helm, we are confident we will continue our strong growth course."

Matthias first joined Wystrach GmbH as Head of Sales in 2020 and helped shape the business’ strong growth trajectory and integration into Hexagon Purus Group. Matthias has a unique combination of experience in technology, business development, and sales. Before he joined the company, he held various positions at an international automotive research and development company, including global technical sales in Japan, China, India, and Europe. “The market for our solutions is growing rapidly. We are very well positioned with our innovative products, product development capabilities and capacity expansion initiatives. I am excited about the opportunity and to contribute to the future of the company in my new role", said Matthias Kötter.

"We are pleased with the outcome of the leadership succession planning and are confident that the future of the company is in good hands," said Jochen Wystrach and Wolfgang Wolter. The founders will support the transition over the course of 2023.

Wystrach to become part of Hexagon Purus - Two market leaders in the hydrogen sector join forces

Wystrach to become part of Hexagon Purus, a global leader in zero emission mobility. The combination brings unprecedented expertise and capacity together to create the industry leader in hydrogen storage solutions.

Hexagon Purus is the leading provider of hydrogen type 4 high-pressure cylinders, fuel storage and distribution systems, and commercial vehicle battery pack and electric drivetrain solutions. The company has more than 50 years of experience with composite high-pressure technology and clean fuel systems. Its European cylinder production facility is located in Kassel, Germany.

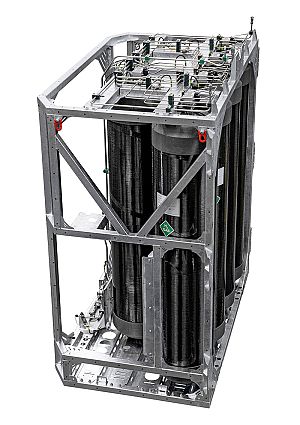

Wystrach specializes in the metalworking required to create the steel structures and piping for hydrogen cylinder systems. It has established itself as an innovation leader in the industry by developing and building end-to-end transport and storage solutions for industrial gases and hydrogen.

The acquistion brings together complimentary capabilities. Wystrach will be Hexagon Purus’ main hydrogen systems assembly hub, based in Weeze, Germany, while cylinder production will continue to be based at Hexagon Purus‘ facility in Kassel, Germany. Together they offer best-in-class expertise and capacity in the growing hydrogen market - and accelerate the energy transition.

Both companies can look back on a long history of successful collaboration. Pioneers in high-pressure technology, Hexagon Purus and Wystrach have both worked to make climate-friendly hydrogen applications a part of everyday life. Hexagon Purus has been delivering high-performance cylinders to Wystrach since 2008 for use in applications ranging from transport, tank systems, stationary storage and refueling solutions.

The acquisition is expected to be complete in the fourth quarter of 2021, and is subject to fulfilment of certain closing conditions and customary regulatory approvals.

Weezer hydrogen technology for energy transition

“We need highly specialized companies like Wystrach for the energy transition. That’s why I’m so happy to be here.” With this statement, German Federal Minister for Economic Affairs Peter Altmaier began his tour of the Weeze-based company on Sunday evening. CEO Wolfgang Wolter also made a rather fitting announcement concerning the company’s next stage of expansion: two new production plants and an office building are set to be built on the company premises next year. This multimillion investment will create 100 jobs.

“We’re delighted that the federal economy minister has chosen to underline the importance of hydrogen technology by visiting our company. Our discussions showed him to be well-versed in the topic and receptive to our concerns. We enjoyed an open dialogue and saw eye to eye,” said Wolter after speaking to the minister. At the start of Altmaier’s visit, both the CEO and Matthias Kötter, Head of Sales, had the opportunity to meet with him for a 45-minute talk, where they exchanged ideas and opinions. The minister was then joined by several guests for a tour of the company. Highlights included a hydrogen tank system that Wystrach had developed for technology company Alstom; the system is used to power trains from the French rolling stock manufacturer with zero emissions. The managers also presented the innovative “WyRefueler” mobile hydrogen refueling station. Altmaier was visibly impressed: “I’ve learned a lot today.”

Funding

The topic of funding for hydrogen projects and networks was also addressed. The economy minister explained that this year’s first funding round had predominantly considered large-scale projects: “That includes projects focused around the switch from coke to hydrogen in the steel industry. ThyssenKrupp alone expressed a need for EUR 700 million in funding.” But he said funds had also been awarded to develop high-performance electrolyzers and build up transport capacity. The next funding phase is aimed at medium-sized companies and looks to ensure that the necessary infrastructure can be created. The minister strongly encouraged Wystrach and its partners to apply again.

Company expansion

Stefan Rouenhoff, CDU politician and member of the Bundestag for the district of Kleve, organized the minister’s visit and emphasized the significance of companies like Wystrach in raising Germany’s profile as a hydrogen leader. “The company is unique in this field and has a huge amount of growth potential.” CEO Wolter was able to verify this appraisal by announcing investments in the “low tens of millions”. These will be used to develop a 20,000 m2 site, which will become home to two new factory buildings and an office complex next year. This growth phase will also create 100 new jobs. “I wish you every success in realizing these plans,” the minister said as he concluded his visit.

Deutsche Bahn chooses Wystrach for hydrogen refueling station

As a partner in the joint H2goesRail project, German rail operator Deutsche Bahn is trialing a green hydrail mobility solution. The system comprises a newly developed hydrogen-powered train together with a plug-and-play hydrogen refueling station. For the latter, Deutsche Bahn has chosen a solution from Wystrach.

Rapid refueling of large hydrogen volumes

“With a view to replacing diesel, hydrogen generated from green electricity is forging a path toward climate neutrality,” says Torsten Schein, CEO of DB Energie. “Refueling that’s as fast, reliable, and competitive as conventional diesel systems is the key to successfully establishing green hydrogen in rail applications. This refueling infrastructure is hugely important—it’s a game changer that will set standards.”

Deutsche Bahn and Wystrach are working closely together to develop the refueling system, which will consist of a 45 ft tank container and a 40 ft refueling station. The latter includes a 500-bar storage unit, a compressor, a hydrogen precooling system, and two sets of refueling connectors. There are two options for supplying the system with hydrogen: either at a designated refueling facility or using electrolysis and compression on-site. Wystrach delivers the control unit and safety technology, and a communication standard between the refueling station and the train is also being developed as part of the project.

Energy-efficient and versatile

As a supplier of hydrogen technology systems, Wystrach can draw on its previous experience: with its WyRefueler, the company’s portfolio features an approved plug-and-play refueling station solution that is already in use in the field. This type of flexible plug-and-play system with intelligent energy management suits the H2goesRail project’s requirements, as it allows the hydrogen refueling station to be set up and operated in multiple test environments. The overall system—the train and refueling station together—is being developed, tested, and optimized by DB Energie.

“H2goesRail is an exciting and groundbreaking project,” says Wolfgang Wolter, CEO Operations and Sales at Wystrach. “Pioneers like Deutsche Bahn are exactly what we need. They’re taking direct action to protect the climate and showing the world that hydrogen technology is a reliable and viable solution in everyday applications. We’re thrilled to be part of this as one of Deutsche Bahn’s development partners.”

Wystrach supplies four 500-bar containers for hydrogen refueling station

Infraserv Höchst has chosen Wystrach as a systems supplier for its hydrogen refueling station under construction in Frankfurt. For this project, Wystrach, a family-owned company based in Weeze, Germany, is providing four 500-bar WyCarrier hydrogen storage systems. The hydrogen refueling station, which is scheduled to open in 2022, will be used for trains that run on fuel cells.

Storage capacity for 4,400 kg of hydrogen for 27 locomotives

“With four 40 ft containers, the storage system has the capacity to hold 4,400 kg of hydrogen. When integrated into the planned refueling station infrastructure, the storage system will be able to service all 27 of the fuel-cell trains currently envisaged for the fleet,” says Elmar Horn, Technical Project Manager at Infraserv Höchst.

Stationary, but also suitable for transportation

Wystrach designs, develops, and builds the containers in Weeze, Germany. “The system incorporates Type IV cylinders for 500-bar storage, providing an optimum cost-benefit ratio,” says Wolfgang Wolter, CEO Sales at Wystrach. “What’s special about our hydrogen storage system is that it’s essentially a stationary solution, but if required, it can be transported on a chassis. ADR certification offers great flexibility for this use case.”

Wystrach provides the tank system for a hydrogen-powered truck

A truck with a hydrogen fuel-cell drive will take to the streets of the greater Stuttgart area this fall. The prototype of the all-electric truck, which has a gross vehicle weight of 26 metric tons, is currently being built within the Hylix-B project. “We want to demonstrate that a fuel-cell truck can be built using components available on the market today,” explains Sebastian Wider, one of the project initiators. “We have the technology, and it’s safe and ready to go.”

Bespoke tank systems with a 350-bar pressure rating

As a systems supplier, Wystrach is providing the hydrogen tank system for the prototype, bringing its vertical integration and its experience with hydrogen applications to the table. “We worked in close coordination with Wystrach to come up with a bespoke tank system and first-class solutions for complex elements, such as the connection between the tank and vehicle,” Wider explains. The installed system comprises five 350-liter tanks, providing capacity for about 40 kilograms of hydrogen at a pressure rating of 350 bar. “Our system operates at a supply pressure of 9 bar and features various safety elements and sensors,” says Robert Stockmann, technical product designer and project lead at Wystrach.

The sharing of experience and a partnership of equals are hallmarks of the Hylix-B project. In fact, the Reallabor project hub is designed to facilitate close collaboration among developers of the individual components and the core team. Led by Prof. Ralf Wörner, a team at Esslingen University of Applied Sciences is managing the project, which aims to research the practicality, economic viability, and social acceptance of using fuel-cell technology in trucks. Funding for the Hylix-B project is provided by the Ministry of the Environment, Climate Protection, and the Energy Sector Baden-Württemberg.

Range of 400 kilometers

“Our prototype will have a range of about 400 kilometers and will be more cost-effective to operate than existing zero-emissions alternatives,” Wider says. “Collaborating so intensively with our partners means we know the components and their optimization potential inside out – and naturally we’ll apply those insights as we continue to develop the technology.”

Plug & play hydrogen storage for research plant in Sweden

The Zero Emission Hydrogen Turbine Center (ZEHTC) project in the Swedish region of Östergötland aims to demonstrate how a pioneering emissions-free and stable energy system can function. The system comprises a photovoltaic system, an electrolyzer, a membrane compressor, a hydrogen storage unit, a fuel cell, pipes, and control units, and the assembly as a whole is connected to a gas turbine test facility.

It is relatively easy to retool gas turbines to handle renewable fuels instead of natural gas. In addition, they can quickly supply balancing power whenever wind, water, or solar power generation dips. The ZEHTC plant will be used to research the control and optimization of this kind of complex energy system.

Robust system for the Scandinavian climate

Euromekanik, a Swedish specialist in gas, energy, and petrochemicals, was involved in developing the system. Specifically, the Euromekanik team designed the gas management setup and its safety features. The project opted for a Wystrach hydrogen storage system. “The high-pressure specialists in Weeze are developing and building a tailor-made plug & play solution,” says Euromekanik Managing Director Peter Rydebrink. “Their entire system will be housed in two 40-foot ISO containers, so all that has to be done at the operating site is to prepare the strip foundations. This will make installation at the project site quick and easy.” The two containers can store around 360 kg of hydrogen.

“In addition to simple handling on-site, we felt it was important for us to offer a solution that is robust enough to work reliably in the Scandinavian climate,” says Wystrach CEO Wolfgang Wolter. The ZEHTC plant is scheduled for completion in the first half of 2021. The project is funded by the Swedish Energy Agency and the ERA-Net Smart Energy Systems program.

Coronavirus / Medical gases

Dear customers,

Like all companies at present, we too are feeling the impact of the coronavirus. Every effort is being made to ensure we meet our delivery commitments. Here at Wystrach, we naturally rolled out the measures recommended by the Robert Koch Institute for containing the virus early on.

However, because the situation is still evolving rapidly, we cannot rule out that our delivery performance will change in the near future. We will do our best to communicate this in due course.

For many things at the moment, it is impossible to say what will happen next. However, it appears that demand for medical gases may increase. This has implications for the provision of bundles as well as periodic inspections. In light of the current situation, now more than ever we want to be able to provide a sufficient volume of products and services. For this reason, we ask that if you have any requests in this area, please get in touch with us promptly at sales_at_wystrach-gmbh.de. Giving us early notice will help us plan our staff capacity accordingly and to order the necessary components quickly.

Thank you for your understanding. Stay healthy!

Jochen Wystrach and Wolfgang Wolter

Pre-assembled H2 tank systems for the world’s first hydrogen fuel cell train

Wystrach supplies tank systems for Alstom’s Coradia iLint

High-pressure systems specialist Wystrach is providing the tank systems for full-scale production of Alstom’s Coradia iLint. “We’re delighted that Alstom awarded us the contract for this prestigious project,” Wystrach managing director Jochen Wystrach says. In its capacity as a systems supplier, Wystrach is providing the components pre-assembled for installation at Alstom’s production facility in Salzgitter.

“For each railcar, we supply two fuel tank compositions (FTCs), each consisting of four modules plus a control system, which were specially developed for installation on the roof of the trains,” explains Wolfgang Wolter, also managing director at Wystrach. With a full tank, the Coradia iLint has a range of around 1,000 kilometers.

The Coradia iLint is the world’s first passenger train powered by a hydrogen fuel cell. In July 2018, the new train became the first of its kind to receive approval for passenger service in Germany. Two models of the train have been in regular service in Lower Saxony for ten months now, both producing zero CO2 emissions. The trains have now completed over 100,000 kilometers in commercial operation and Dr. Jörg Nikutta, Managing Director for Germany and Austria at Alstom, is “thoroughly satisfied” with how they are performing.

With Lower Saxony’s regional public transport organization, Landesnahverkehrsgesellschaft Niedersachsen, having ordered 14 of the hydrogen-powered trains, its Hessian counterpart, Rhein-Main-Verkehrsverbund (RMV), has now followed suit: in May 2019, RMV ordered 27 Coradia iLints—the largest fleet of fuel cell trains in the world.